Hi there! In this article, we're going to cover everything about s. Have you ever witnessed someone weld? It is a very fun job where you help to build an important stuff! When, people weld, they melt two pieces of metal together with a special metal stick called a welding rod. The 4043 aluminum welding rod is a special aluminum welding rod that many welders love to use. Take a look at what makes it so popular and how you can use it to create awesome heavy duty welds!

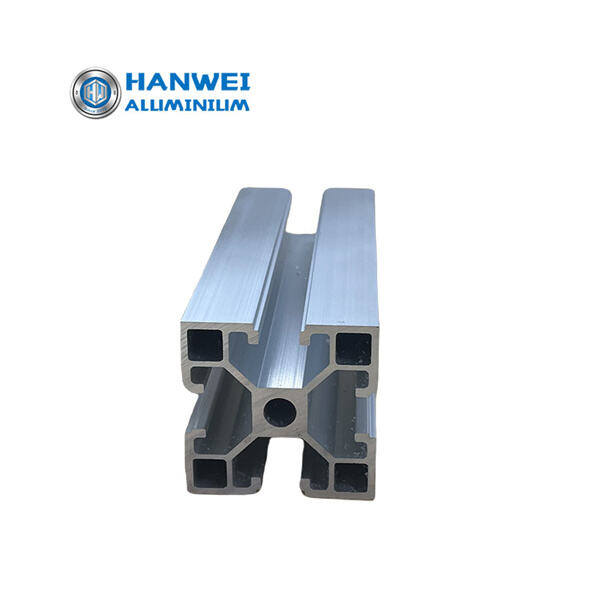

The 4043 aluminum welding rods are composed of aluminum & magnesium & silicon combination. This unique combination gives it a lot of strength, ideal for welding aluminum. The rod melts when used, and this melting binds the metals. It’s also just super shiny and pretty when you weld it. This is critical to producing things that people actually look at, too, like car parts or airplane wings that must look aesthetically pleasing. The other awesome thing about the 4043 aluminum welding rod is that its really easy to use, even if you are new to welding!

Caring Estimators appreciate the 4043 aluminum welding rod since it has several advantages to further facilitate and excel their work. First of all, it can be employed on a variety of aluminum types so it is great for a range of projects. This means this rod can help you whether welding thin sheets or thicker pieces. It has another cool characteristic: a low melting point. This allows it to melt with less heat than other welding rods. This makes it easier to use and helps you protect the metal you are working on, so you do not endup damaging it. Last but not least, the 4043 aluminum welding rod provides nice, clean welds. This is ideal for projects where appearance is the crux!

Now that we know how amazing 4043 aluminum welding rod is, let’s chat about its use for perfect weld! However, before that you will need to invest in the correct welding machine for your project. There are many different types of welding machines, and the amount of choice can affect your productivity. Then you need to choose suitable welding rod size according to the thickness of the metal you weld. For best results, you need to fit the size of the rod to the thickness of the metal. Then, ensure the pieces of metal that you weld are cleaned of dirt, oil, or debris. If the metal is dirty, the weld may not stick. You can start using this rod and learn it to make it smooth and even welds. So just keep practicing, practice makes perfect!

4043 aluminum welding rods are available in several different variations. This can lead to some confusion about which one is the best fit for your project. So, the first step in choosing the right welding rod is to consider what type of metal you are welding. That means selecting a rod that works with that particular alloy of aluminum. And consider how thick the metal is, too. When welding thin metal, use a smaller diameter rod than when you are working with very thick metal. Finally, decide what kind of finish you’d like. Do you want a glossy look or matte? Choosing a appropriate rod can help you get the look you’re going for.

Now you know how to pick the right welding rod, and how to complete perfect welds! Welding Tips Using 4043 Aluminum Welding Rods The first one is to keep the welder’s rod as clean and dry as possible between the weldings. This is to keep it from dirtying as it can influence the manner by which it works. As for welding is concerned, you can also try different welding methods to find out which technique you feel most comfortable working with. Everyone has different ways that work; experimentation will help you find yours. Finally, never forget to wear personal protective equipment like gloves and helmet to protect yourself when you weld. Always remember that it is the priority!

With a diverse market layouts and an international service system, our products are available to various nations and regions around the world, encompassing major markets like Southeast Asia, Europe, and the Americas. To be able to react quickly to global customer requirements, the company has developed a complete global logistic network. Additionally we have a multilingual customer service staff to provide expert technical assistance and support to all customers in the globe.

Our highly skilled after-sales personnel will provide customers with quick technical support, and solve problems. Our after-sales staff will offer customers the most effective solutions regardless of whether they require custom cutting as well as feedback on quality issues. In addition, we provide a regular customer return visit service to learn about the needs of customers and implement feedback in a timely manner in order to continually improve our customer service.

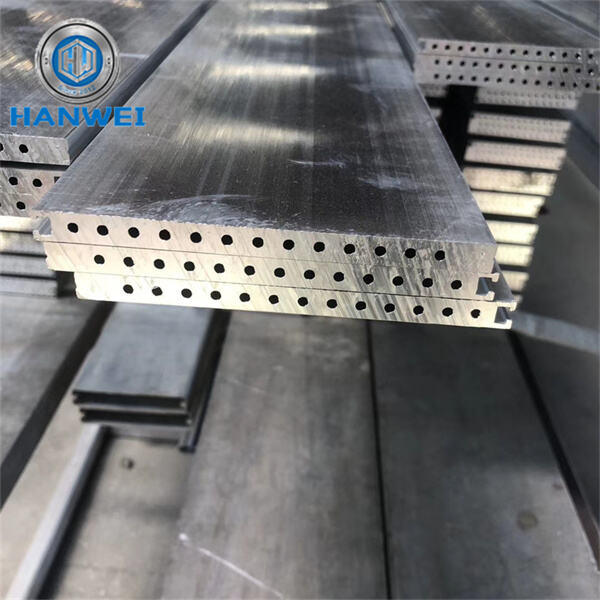

Our company is able to offer a vast assortment of titanium, aluminum and various metal materials, covering a variety of specifications and models to meet the requirements of our customers. At the same time we have developed its own logistics process that ensures that the items are delivered to customers within the shortest possible time. We can respond quickly to customer demands that are urgent with the flexibility of our inventory management system and speedy delivery capability. This helps customers reduce production time and increase efficiency.

We're dedicated to providing flexible, personalized solutions that meet the demands of each client. Through personalized and in-depth services we provide customers with not just materials but also complete solutions that are in line with their application and design needs.