Aluminium rods for welding are very essential equipment which are used by several jobs and industry. A company that produces such rods is Shanghai Hanwei. This is what you will learn in this text about aluminium welding rods. In this article, we will explore what aluminium welding rods are, where they can be used, why it is helpful, how it eases people to work faster, and the types of aluminium welding rods that are available for different projects.

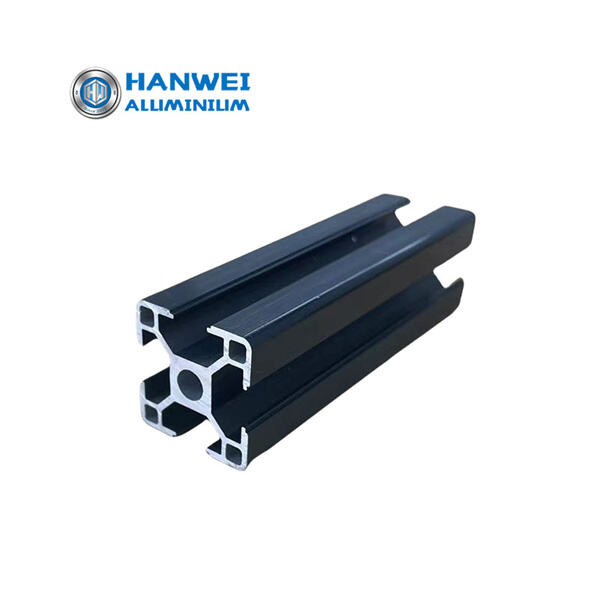

Aluminium welding rods are made from metal known as aluminium. Aluminium is lightweight but also extremely strong, so it's an excellent material for numerous applications. One of the major advantages of aluminium is that it doesn't rust, so can last a long time in the presence of moisture. Moreover, aluminium can withstand high heat without being spoiled. Aluminium welding rods are capable of doing a lot of welding jobs. The other property that makes aluminium welding rods is electrical conductivity.

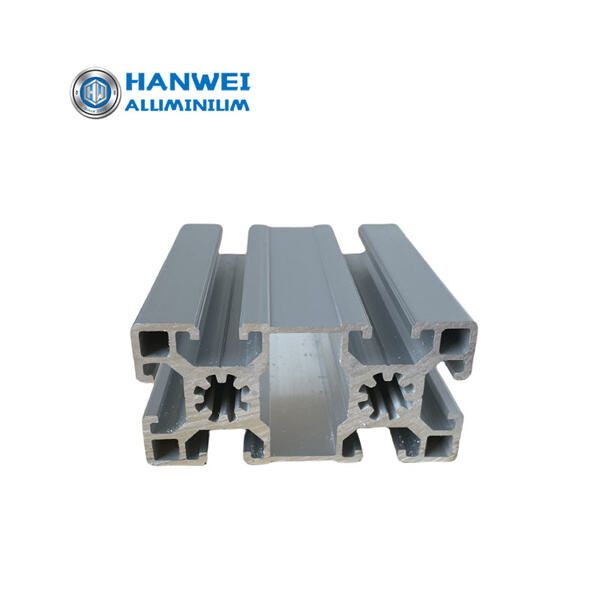

Aluminium rods are used in various industries which include automotive, aerospace, construction, and manufacturing. Aluminium rods are used to join two pieces of aluminium together in each of these areas. This joining process is important for the construction of many things, including tall buildings and fast airplanes. In the automotive field, aluminium welding rods are frequently used to repair any damaged vehicle bodies and frames. The basic purpose of these rods is to help in the assembly of various parts in the aerospace industry. Many of the tools that we use every day to make and fix things would be a lot harder, if not impossible, to create without aluminium rods.

Benefits of using Aluminium Welding rods There is a number of benefits of aluminium welding rods. In first, they are way user-friendly and easy to handle. Timely using aluminium rods, welders require less heat than other welding materials. This lower heat requirement helps to minimize the risk of bending or warping the metal being welded together. Second, aluminium welding rods produce extremely clean and tidy welds. This is significant because a visually appealing weld is often required especially if the end product should be pleasing to the eye. Thirdly, welding rods for aluminium are inexpensive and readily available in shops. Thus aluminium rods are available to both hobbyists and professionals, as well as businesses.

How Aluminium Welding Rods can Contribute to Increasing Productivity? First, since they require less heat and time to weld, workers have the chance to do more work in less time. That means jobs can be completed quicker, allowing companies to tackle additional projects. Second, the tidy and clean welds that aluminium welding rods produce require less time and effort spent cleanup. If welds look good immediately, there is less demand for post-weld grinding. Finally, as aluminium welding rods are cheap and accessible, companies can save costs on the welding as compared to using expensive welding material. This savings can accumulate and allow for more efficient operations.

If you are seeking to make an aluminium welding rod, you will find several types of aluminium welding rods. The rods come with unique features that make them fit for certain purposes. Some of these rods are identified below:

4043 Aluminium Welding Rod: 4043 rod is regarded as one of the most widely used rods for welding aluminum to aluminum or fusing metal of two different types. It is very versatile and works across many use-cases.

We have created a professional after-sales team that is able to provide customers with rapid response technical support and problem solving. Our after-sales personnel will give customers the best possible solutions, whether it's custom cutting and consultation, or providing feedback on issues with quality. Additionally, we offer a regular return visit service to understand customer needs and use feedback promptly in order to continually improve our customer service.

With a wide range of market layout and international service, our products are distributed to numerous countries and regions around the world, encompassing important markets like Southeast Asia, Europe, and the Americas. The company has built an international logistics network in order to rapidly respond to the needs of global customers. In addition, we have a multilingual customer service team to provide skilled technical support and services to customers around the globe.

We have a wide inventory of titanium, aluminum and other metals in different models and specifications to suit the needs of our customers. The company also has its own logistic system, which ensures that products are delivered in the shortest time feasible. Flexible inventory management as well as speedy delivery capabilities allow us to quickly respond to urgent requests from customers, helping customers save time in production and increase efficiency.

We are committed to offering custom-designed, individualized solutions that meet the demands of each customer. We offer our customers personalized, in-depth service that does not just include materials but also solutions to meet their design and application requirements.