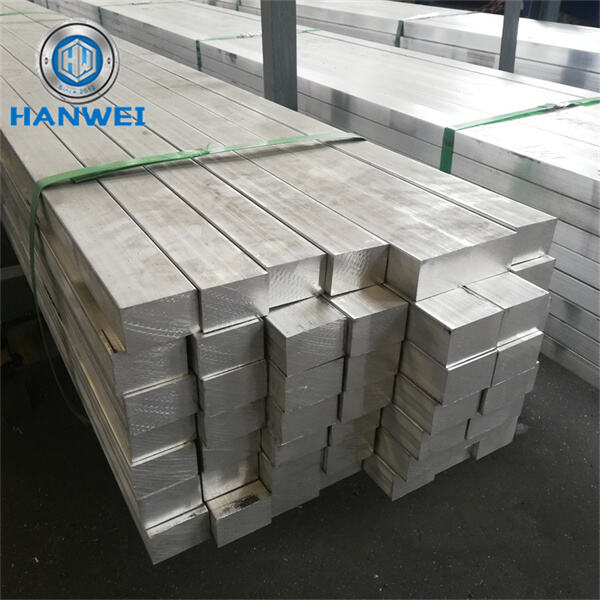

Aluminum flat bar is a popular choice among DIY enthusiasts and construction workers alike when it comes to constructing something that needs to be strong and flexible. This type of metal is an excellent choice for a wide range of projects, as it is very versatile. Shanghai Hanwei is a professional manufacturer and supplier of 2 inch aluminum flat bar. It is considered robust and flexible, for which it can be used in numerous ways. In this article, we will cover what aluminum flat bar is, the pros and cons of using aluminum flat bar, how to choose the right thickness for your application, how to cut and shape it, and why aluminum flat bar is an excellent choice for your project.

Aluminum flat bar is a long strip of metal made from a light-weight aluminum alloy. So it is not too heavy, so it is easy to work with. There are many different widths (how wide it is) and thicknesses (how thick it is) that come from different tree species so it can be used for a wide array of applications. They can range from making industrial machines, to fun home projects, such as furniture building or home decoration. Unlike other tools, the flat shape makes it usable in most situations where a straight, solid surface is required. Aluminum flat bar is also one of the best materials to use if you do not want your product to get rusty because it can be used for many years if correctly taken care of and used even for outside locations. It’s also light and can be shaped into many shapes.

Flexibility is one of the greatest advantages of 3 inch aluminum flat bar. This means that it is very malleable, and can be shaped into a variety of different forms, and as such, it is an ideal metal for the most diverse DIY projects. It is also lighter than other metals, so it is popular with those seeking weight or transportation cost savings. The second and even better thing about aluminum flat bar is its rust resistance. This provides greater durability over time in outdoor environments where other metals may not particularly stand up to wear and tear as effectively.

But for all its advantages, aluminum flat bar has also its disadvantages. To illustrate, it is not as strong as some metals such as steel. That also means it can be scratched or dented more easily, which means it may not be suitable for areas that need to bear heavy weights or endure hard impacts. Particularly, aluminum flat bar does not have high resistance to certain heat environments or harsh chemicals compared to some other materials.

There are really several advantages you will find when cutting and shaping aluminum flat bar. This could be a saw, grinder, or shear. If you want to get your hands dirty, you could opt for a hacksaw or a jigsaw, which are effective for smaller cuts. If the cut is more complex, a circular saw can be helpful. Regardless of the method you chose to employ, always remember to protect yourself by putting on safety gear. This will include goggles to shield your eyes and gloves to shield your hands.

Aluminium flat bar is also excellent for various DIY applications in addition to construction applications. You can create custom shelving or bookcase or picture frames that fit your style. You can also use it as decorative trim or accents, giving a unique element to whatever it is you are working on. This versatility accumulates to aluminum reel bar in a widespread choice amongst DIY enthusiasts.

Lightweight, cost-effective metal: Perhaps the greatest benefit of aluminum flat bar is that it is a relatively cost-effective metal compared to other metals. Most importantly, it is significantly cheaper than steel, making it an ideal material for those looking to keep costs as low as possible whilst also maintaining a quality material. And since aluminum flat bar is light, it can lead to savings in transportation and material costs, which is particularly significant in the case of bigger projects.

We have created a professional after-sales staff that can offer customers quick response technical support and assistance in solving issues. If it's custom cutting consult, using consultation, or high-quality feedback for a problem, our after-sales team can provide customers with a satisfactory solutions as soon as possible. We also provide a frequent return visit service for customers to understand their requirements and to use their feedback.

We adhere to the principle of "customer first" We are committed to providing flexible and personalized solutions that meet the specific needs of different customers. Through personalized and in-depth services we provide customers with not just products as well as overall solutions that meet their product design and application needs.

With a diverse market layout and international service system, our products are available to various countries and regions around the world, covering major markets such as Southeast Asia, Europe, and the Americas. The company has built an entire international logistics system to ensure that it can swiftly respond to the needs of global customers. At the same time, we have a multilingual customer service staff to provide high-quality technical support and assistance to our customers all over the world.

Our company has a large collection of titanium, aluminum and various metal materials, that cover a wide variety of models and specifications to meet the needs of different customers. Furthermore we have developed its own logistics system to ensure that the products can be delivered to customers within the shortest possible time. Flexible inventory management and quick delivery capabilities allow us to be able to respond quickly to urgent requests from customers, helping customers save time in production and boost efficiency.