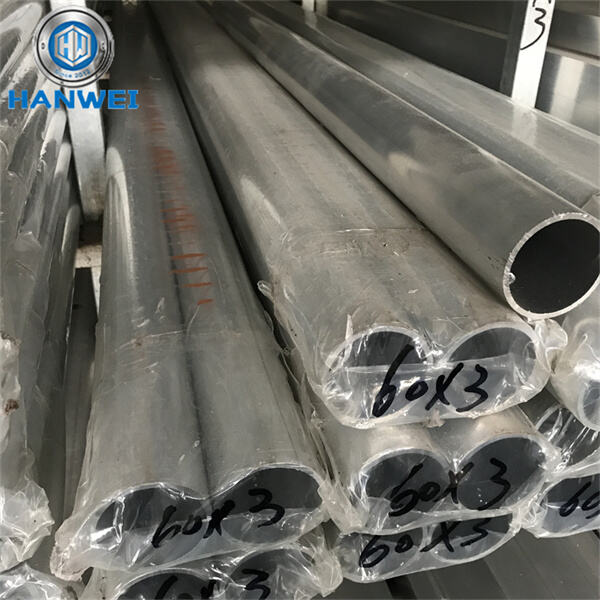

This means you can get your parts produced much more easily, as no special tooling is needed to mold round tubes as would be required for a different shape. They look a lot like straws! These cylinders vary in size and thickness and can be relatively thin or very thick. This is why 1060 aluminum round bars are commonly used in a variety of locations and applications. Let’s take a closer look at the advantages of aluminum round tubes, the various design options, how they can be assembled, and different types of decorative finishes.

Aluminum round tubes also do not rust, which is another great thing about them. So that means they can be used outdoors without fear of moisture or rain damaging them. They are ideal for outdoor projects and environments because they will never rust or decay over time. Moreover, aluminum round tubes are extremely durable. That's why they are often used in construction and engineering, because they can withstand so much pressure. And this strength makes them a good option to build things that are needed to last.

There are a wide variety of shapes that 1100 aluminum round bars can be manufactured into making them extremely valuable. They might be hollow, or empty inside, or they can be solid, full inside. If you are determining whether you need hollow or solid tubes, it depends on the capability that you need the tube to perform. For instance, if you want a tube that moves liquids or gases, then a hollow tube is generally the right option. For these applications, hollow tubes are ideal, as they let liquids or gases flow freely through them.

A solid tube might be your best option for a stronger, more heavy-duty tube if it is important to you. Solid tubes are generally heavier and can even bear more pressure. Speaking of thickness, the thickness of the tube can also differ depending on what you need to use it for. For lighter items and gadgets, a thinner tube is usually enough. However, if you're taking heavier machines or tools, will need a thicker tube to make sure it is strong enough. With the ability to manufacture custom tubes at Shanghai Hanwei, you will get exactly what you want!

When joining together two pieces of metal, welding is an essential procedure. It refers to melting the edges of metal with heat and scraping the pieces together. You could also learn the processes of welding like TIG and MIG. This is, when aluminum round tubes are welded, it is essential to use the proper welding procedure to ensure that the joint is solid and secure. We at Shanghai Hanwei prefer aluminum tube TIG welding, the common and reliable method of welding aluminum tubes.

Polished finish, which gives the tube a shiny look and smooth appearance. This reflects a smoother surface can add a professional and nicer touch to your project. An anodized finish is a different process; it applies a unique protective layer to the aluminum. The layer adds durability and prevents the tube from getting damaged with time and usage. What this means is that it will survive longer, even in arduous conditions.

There is also a powder-coated option. This finish is achieved by applying a thin layer of dry powder to the metal, then baking it on. This method forms a durable and scratch-resistant layer, defending the tube from scratches and preventing potential damage. There are different types of finish and each type has its own advantages, and we are here to help you decide which one of these would benefit you the most based on your requirements and how you will be using the aluminum round tubes.

We have a wide inventory of titanium, aluminum and other metals in different models and specifications to suit the needs of our customers. The company also has its own logistic system, which ensures that products are delivered in the shortest time feasible. Flexible inventory management as well as speedy delivery capabilities allow us to quickly respond to urgent requests from customers, helping customers save time in production and increase efficiency.

Our professional after-sales staff will provide customers with quick technical assistance and assist in solving issues. Our after-sales personnel will give customers the best solutions regardless of whether they require custom cutting with consultation or feedback on quality problems. We also provide a frequent returning visit for customers to better understand their needs and to use their feedback.

With a wide range of markets and an international service, our products are distributed to numerous regions and countries around the world, encompassing important markets like Southeast Asia, Europe, and the Americas. The company has set up an extensive international logistics network so that it can swiftly respond to the demands of its global customers. At the same time, we have a multilingual customer service staff to provide professional technical support and services for customers from all over the world.

We are committed to offering custom-designed, individualized solutions that meet the demands of each customer. We offer our customers personalized, in-depth service that does not just include materials but also solutions to meet their design and application requirements.