Aluminum is a lustrous and lightweight metal that is found in several items of our daily lives — from IPhones to kitchen utensils. Because aluminum is strong and rust-resistant, it can last for a long time. Aluminum is available in the common shape of a square bar. In this introduction, we will be exploring some of the reason why engineers prefer, and what makes aluminium square bars so fantastic for their unique projects.

One important feature is that aluminum square bar stock are very strong and are able to hold a lot of weight without breaking. They are also light, which makes them easier to carry and work with. Aluing this strength and lightness allows this flock to be used in a bunch of different projects. They do not rust or corrode, so they can live a long time without replacement or repair. Aluminum is easy to work, so these bars can be cut, drilled and shaped to make different forms without cracking or falling apart. That makes them very useful for builders and engineers who need reliable materials.

Engineers love aluminum square bars because they produce the same shape and size every single time since they are made. This is useful, as this means engineers could rely on it to behave well in their systems. For instance, say an engineer is designing a machine that needs to interlock precisely, the engineer can utilize aluminum square bars to ensure proper alignment. This consistency leads to less time being spent trying to solve issues, and it also means less materials are wasted in the design and construction phase. It allows engineers to focus on improving their projects instead of worrying about whether the materials will fit.

Here are the advantages of aluminum square bars over other materials. They are very strong, though light, so they work well for projects where you need strength and easy moving. They are excellent for outdoor use where they might be exposed to rain or other weather conditions since they do not rust. Aluminium is also a good conductor of heat and electricity, so aluminium square bars be utilized in significant electrical and warming occupations. So, they are quite multi-purpose and can be used in numerous applications.

Aluminum square bars are used by engineers for special use cases due to their flexibility, ease of use, and consistency. Aluminum is a choice material among engineers for its strength, light-weight quality and rust-resistant property. Engineers also love the fact that aluminum can be formed into diverse profiles as per project requirements. Aluminum square bars are specifically used when engineers need a material they can depend on, while not being too difficult to work with and providing the same results, over and over again. This helps them create better designs and builds that fit their needs.

Square bars of aluminum are used in various industries for a numbers of different applications. In the automotive sector, for example, engine parts, wheels, and a plethora of other fast-moving parts within a car are manufactured using aluminum square bars. In construction, they are used to make the structural framework for windows and door frames and roofing materials. Aluminum square bars are equally vital in the production of boats, airplanes, and bicycles. Aluminum's low weight and high strength make it a good choice for medical equipment and electronic devices as well as enabling easy handling of the equipment while retaining its robustness.

With a diverse market layout and international service systems, our products are offered to a variety of nations and regions around the world, and cover major markets like Southeast Asia, Europe, and the Americas. The company has set up an extensive international logistics network to ensure that it can quickly meet the demand needs of global customers. We also have a team of customer service representatives multilingual for technical support that is professional for our customers across the globe.

We're dedicated to providing customizable, flexible solutions that are able to meet the requirements of every customer. With personalized and comprehensive solutions We provide our customers with not just the materials they require as well as overall solutions that are in line with their specific product design and requirements.

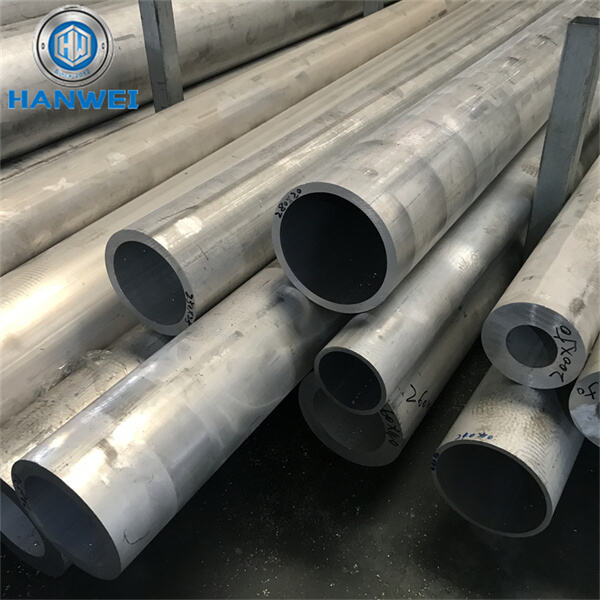

We have a wide inventory of aluminum, titanium, and other metals, in several designs and specifications that meet the needs of our clients. The company also has its own logistic system, which makes sure that products arrive in the shortest time possible. We are able to respond quickly to customer demands that are urgent with the flexibility of our inventory management system and speedy delivery capability. This helps customers reduce the time of production and improve efficiency.

Our professional after-sales staff will provide customers with quick technical assistance and assist in solving issues. Our after-sales personnel will give customers the best solutions regardless of whether they require custom cutting with consultation or feedback on quality problems. We also provide a frequent returning visit for customers to better understand their needs and to use their feedback.