Extruded aluminum bars are unique building materials architects and builders everywhere use to form all kinds of structures. Including bridges which allow automobiles as well as individuals to pass rivers, conditions reaching the sky, and also automobile including cars and trucks and buses. These bars go a long way in creating strong frameworks, supports and panels in these buildings, which are why they prove to be so useful. So in this article, we are going to find out why are an excellent and great option for the construction of projects and how things like these can really make building easy and less time-consuming.

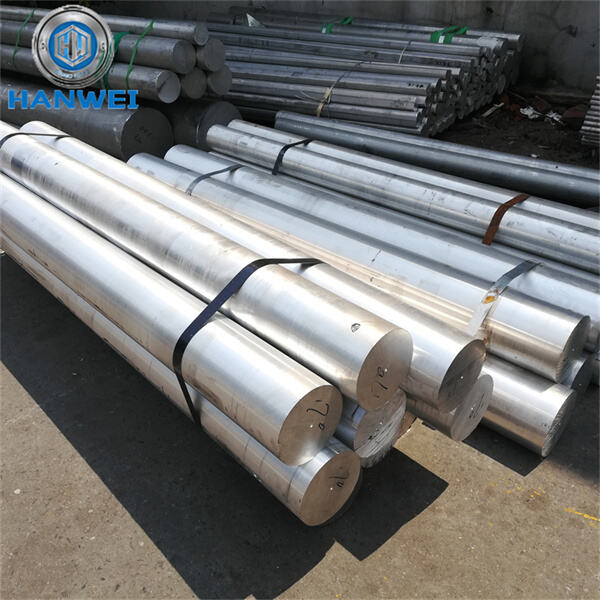

There are great advantages to the builder to using extruded aluminum bars. First, they are incredibly lightweight and extremely strong, making them ideal for outdoor structures and buildings. They are also highly resistant to rust and corrosion, so their material will not get damaged because of the exposure to rain or other weather conditions. That’s why they have a long lifespan and are still safe to use. Also, the extruded aluminum bars can easily take different shape. This makes it super convenient for builders and architects that would like to design interesting builds.

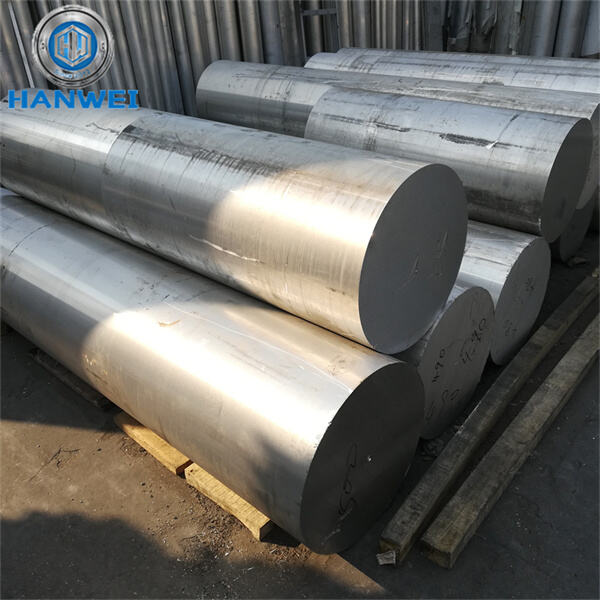

The primary reason that builders prefer extruded aluminum bars is because they are simultaneously lightweight and strong. These bars are far lighter than common materials such as steel or concrete. They are also easier to carry, move, and work with on construction sites because of their low weight. Meaning workers can transport them without becoming overly fatigued. But they're also very strong, despite being light. These have a high strength-to-weight ratio (they can support very heavy loads without breaking or bending). They are a dependable choice for constructing robust structures.

The successful assembly of structures revolves around the use of materials which fit well and look good. Extruded aluminum bars are known for their precision and consistency. These bars can be customized by builders based on size and shape, thus making them a perfect fit in any project. This also goes with industries that principally depend on some principles like having a specific size for a frame or support, it is easy to get it made as per their need (like the projects). Also, since they are made in an extrusion process, these bars will have a uniform color and texture. This reduces further finishing or painting, thus speeding up and simplifying the construction process.

Choose extruded aluminum bars if you are one of those people who care about the environment. Aluminum is the most recyclable material as it can be reused in new projects indefinitely. Which is great because it helps to reduce waste and protect our planet. Recycled aluminum bars Image: WAYDO Image: WAYDO Image: WAYDO Image: WAYDO “By using recycled aluminum bars, builders can further reduce their carbon footprint, which is the amount of greenhouse gases that they emit. In addition, the process to make extruded aluminum bars is less polluting than producing materials such as steel or plastic. Thus, aluminum is a green building material for any construction project.

An additional awesome advantage of extruded aluminum bars is that they could build the quality and usefulness of structures to an extraordinary degree. Bar welding has a different key service, which is, by combining these bars well, the builders can build complex, multi and unique patterns. Or, whether it’s a stylish contemporary tower dominating a cityscape or a finely-detailed old-school edifice, aluminum bars can help bring these designs to fruition. They can also be layered with other materials such as wood, glass or as plastic. Because of its versatility,extruded aluminum bars and shapes are an integral element in bringing architect's or engineer's concepts to life.

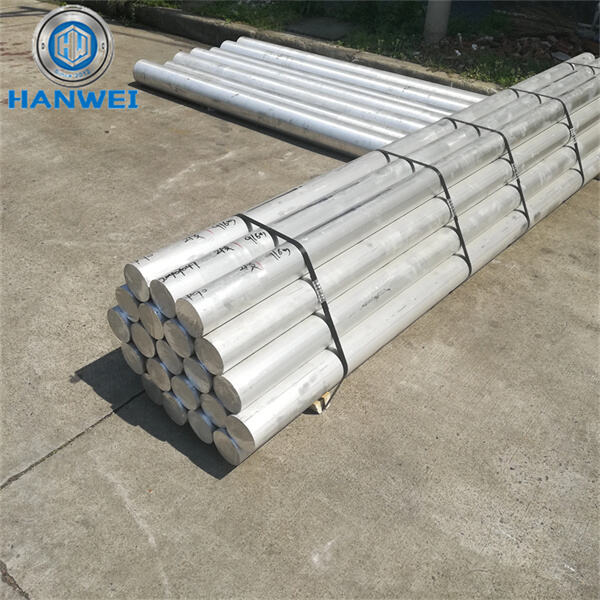

Our company is able to offer a vast assortment of titanium, aluminum and various metal materials, covering a variety of specifications and models to meet the requirements of our customers. At the same time we have developed its own logistics process that ensures that the items are delivered to customers within the shortest possible time. We can respond quickly to customer demands that are urgent with the flexibility of our inventory management system and speedy delivery capability. This helps customers reduce production time and increase efficiency.

Our expert after-sales service team provides customers with fast technical support and can help with issues. Our after-sales representatives will offer customers the best solutions whether it's cutting custom as well as feedback on quality issues. We also provide a frequent return visit service for customers to help them better understand their needs and then use their feedback.

In keeping with the concept that puts the "customer first" We are committed to providing flexible and personalized solutions that meet the specific demands of various customers. Through individualized and thorough services we provide customers with not just the materials they require, but also overall solutions that match their specific product design and demands.

Our products are sold in many countries around the world and include Southeast Asia, Europe and the Americas. To ensure that it is able to react quickly to global customer requirements, the company built a complete international logistic network. In addition we have a multi-lingual customer service staff to provide expert technical assistance and support to all customers in the world.