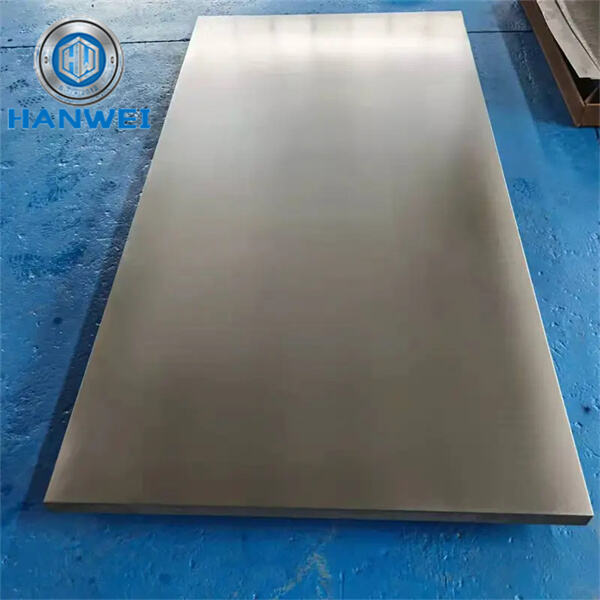

Moly plate is a very special type of metal plate. This metal, silver in hue, is exceedingly strong and durable. It is extremely strong, making it ideal for many applications, especially those that may be subjected to high heat. Due to its unique physical and chemical properties, has been utilized in various industries to manufacture some essential components and products.

It has some really awesome features that makes Molybdenum plate different from others. It was rated highly for one essential feature: It doesn't rust or break down easily. It allows it to remain functional for a long time even if it is operating in harsh environments, be it too much heat or rugged conditions. It is a very strong material and therefore can withstand high pressure without breaking. That endlessly reproducible 9 position is perfect for all sorts of applications from cars and airplanes to machines and medical instruments.

For industrial applications that involve high heat, molybdenum plate is the optimal choice. Even those steamy sweaty heats where it can hold up and wont melt. That is why it is commonly used in car engines, where the heat is often extreme. Components such as pistons and cylinder heads necessary for engine operation are made from molybdenum plate. It is is also used in planes and jet engines, because it can stand up to the extreme heat and pressures encountered in flight and allow everything to operate smoothly.

Molibdom plate helps the companies in saving money in long run. Because it doesn’t rust, companies need to replace it less frequently than rust-prone metals. Its resistence to any rust makes that, right away, which can help sheltering buildings from damage from the weather and other wear. Molybdenum plate is also used in the oil and gas industry where it prevents the rusting of pipes and for the protection against corrosion, saving money and keeping the system running.

It is highly tough and strong, and therefore, molybdenum plate is used. This is the reason it is widely used in the medical industry for making surgical instruments and other vital medical equipment. These tools must resist high levels of stress and pressure, whereas molybdenum plate is strong enough to keep them that way. It is also utilized in the electronics industry to manufacture components that must be strong and reliable. It is also crucial for the energy industry, which uses it to fabricate components for nuclear reactors and other power plants, allowing electricity to be produced safely.

Molybdenum plate is highly versatile and is used in a wide variety of industries. In aerospace, it is used to manufacture components for airplanes and spacecraft, ensuring they withstand the rigors of flight. In the automotive industry, it is used to manufacture engine parts and other components that require strength and reliability. Molybdenum plate is also used in the medical field to produce surgical instruments and medical tools that are required by hospitals and doctors. Moreover, this material is essential to the electronics industry, contributing to the assembly of components that withstand high stress levels. Finally, molybdenum plate plays an important role in the energy sector, particularly in producing components for nuclear reactors and other types of power plants that generate energy for communities worldwide.

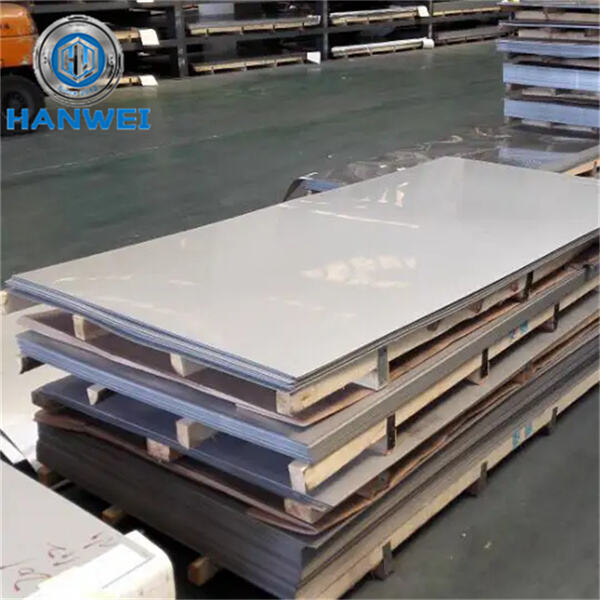

Shanghai Hanwei, Manufacturer, Focusing on Molybdenum Plate and Metal Products They specialize in not just molybdenum metal plate but also a variety of other seals quality metal plates such as tungsten plate, tantalum plate & many more. They make sure to use strict quality standards for the making of all their products leaving no room for compromise and ensuring that best quality product reaches the end customer. Shanghai Hanwei understands that customer satisfaction is key, as well as providing competitive prices and fast delivery times that help the business get the metal products at their convenience.

The company's inventory is extensive. collection of titanium, aluminum and other metal materials, offering a range of models and specifications to meet the needs of different clients. In addition the company has developed its own logistics system that ensures that the products can be delivered to customers within the shortest possible time. Flexible inventory management as well as speedy delivery capabilities allow us to be able to respond quickly whenever customers need urgent help and help customers cut time in production and boost efficiency.

Our highly skilled after-sales personnel will provide customers with quick technical support, and solve problems. Our after-sales staff will offer customers the most effective solutions regardless of whether they require custom cutting as well as feedback on quality issues. In addition, we provide a regular customer return visit service to learn about the needs of customers and implement feedback in a timely manner in order to continually improve our customer service.

We adhere to the principle of "customer first" We are dedicated to providing flexible and customized solutions to meet the distinct needs of different customers. Through individualized and thorough services we provide customers with not just products, but also overall solutions that match their specific product design and demands.

With a wide range of market layout and international service, our products are distributed to numerous countries and regions around the world, encompassing important markets like Southeast Asia, Europe, and the Americas. The company has built an international logistics network in order to rapidly respond to the needs of global customers. In addition, we have a multilingual customer service team to provide skilled technical support and services to customers around the globe.