Titanium is a very strong and lightweight metal, so is a metal that is strong and lightweight. That essentially translates to being lightweight but pressure resistant. Things that won’t rustTitanium does not rust or corrode. This is very important as it means that the piece of titanium round bar can endure for a long time even under harsh conditions like salt water and extreme temperatures. And titanium is also biocompatible. So it is biocompatible and can be used for medical implants without being damage or introducing any harm or health problems. This is extremely high value when it comes in the field of medicine.

First, workers remove titanium from its ore with a special chemical process. This is the first stage where the metal is prepared. Once the titanium is removed, it gets melted down and cast in a mold by pouring it into a block shape called an ingot. Picture the ingot as a big hunk of metal. Then this ingot is scattered and condensed into a smaller piece known as a billet. This initial part will shape the raw titanium round bar into the final piece that we observe.

The titanium billet is then reheated and placed in a machine that presses the material through a geometric shape called a die. How the titanium round bar is finally shaped up? In concrete terms, once the bar has been fully shaped, it is subjected to a series of stringent quality tests. These tests are very crucial as they ensure that the titanium round bar fulfills the top quality marks for safety and performance.

There is quite a number of benefits of utilizing titanium round bar in different fields. One of the best things about it — its strength relative to weight. Titanium weighs half as much as commonly used steel products, but is equally strong. That is why titanium is a very good material for parts in planes, rockets, cars and even sports equipment. Moreover, as it has the characteristics of being light but strong, this contributes to better performance and efficiency in not only these two key areas but in many more.

Another key property of titanium is its high resistance to rust and corrosion. That is why it is a great material to work with in marine applications, such as boats and offshore oil rigs. It’s not likely to wear out, so it can help save money on repairs and replacements over time. Another reason titanium is such a great material for medical implants and surgical instruments is because of its safety and non-toxicity. That is very important for the health and safety of patients.

In addition, titanium is capable of withstanding extreme temperatures, both hot and cold. Incredible, at 600 ° C (1112 ° F), it is still strong; Titanium remains ductile under extremely cold conditions — it can bend without breaking. This property allows titanium round bar to be suitable for both hot and cold applications.<|end_of_post|>

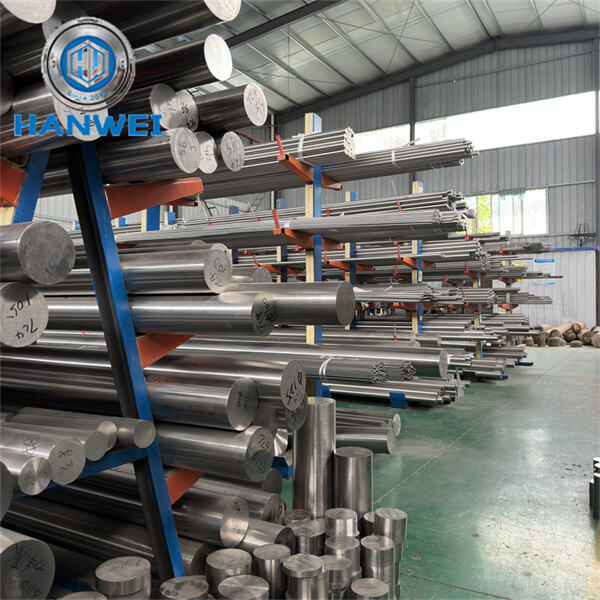

Titanium Round Bar Size Options from Shanghai Hanwei This variety can help customers choose the right size and shape for their particular application. The titanium round bar has a diameter ranging from a few millimeters to over a foot wide (6 inches or more). Also, customers can have the bar length tailored according to their precise specifications and performance requirements. That means that, regardless of what you are making, you can always be sure the types of titanium round bars you require for your project will be available.

With a wide range of markets and an international service, our products are distributed to numerous regions and countries around the world, encompassing important markets like Southeast Asia, Europe, and the Americas. The company has set up an extensive international logistics network so that it can swiftly respond to the demands of its global customers. At the same time, we have a multilingual customer service staff to provide professional technical support and services for customers from all over the world.

We have created a skilled after-sales department, which is able to offer customers quick response technical assistance and solutions. It doesn't matter if it's cutting custom, use consultation, or quality problem feedback Our after-sales staff can provide customers with a satisfactory solutions as soon as it is possible. We also offer a regular return visit service to learn about the needs of customers and use feedback promptly and continuously enhance the quality of our service.

As a firm believer in the concept that puts the "customer first" We are dedicated to providing flexible and customized solutions to meet the individual demands of various customers. Our customers receive customized, comprehensive service that does not just include the materials, but also solutions to fulfill their design and needs.

Our company has a large collection of titanium, aluminum and various metal materials, that cover a wide variety of models and specifications to meet the needs of different customers. Furthermore we have developed its own logistics system to ensure that the products can be delivered to customers within the shortest possible time. Flexible inventory management and quick delivery capabilities allow us to be able to respond quickly to urgent requests from customers, helping customers save time in production and boost efficiency.