One of the best materials is , which has been widely used for various applications. First and foremost, it is unbelievably strong. So it is able to stand a lot of pressure without break; this can be crucial in many cases. For example, in airplanes, components made from titanium must withstand the enormous forces present when soaring high in the sky. Titanium sheet has another wonderful property and that is, it is too light. It is this property that makes it desirable in the aviation and aerospace industries, where maintaining a lightweight is extremely important.

Salt water (and most chemicals) cannot damage titanium, unlike many other metals. So I think it's a nice way to go for tools and devices that will be directly exposed to such stuff, for instance, in a marine environment or in hospital. Due to its unique characteristics, titanium sheet is an extremely durable material that numerous industry sectors rely on to make their products.

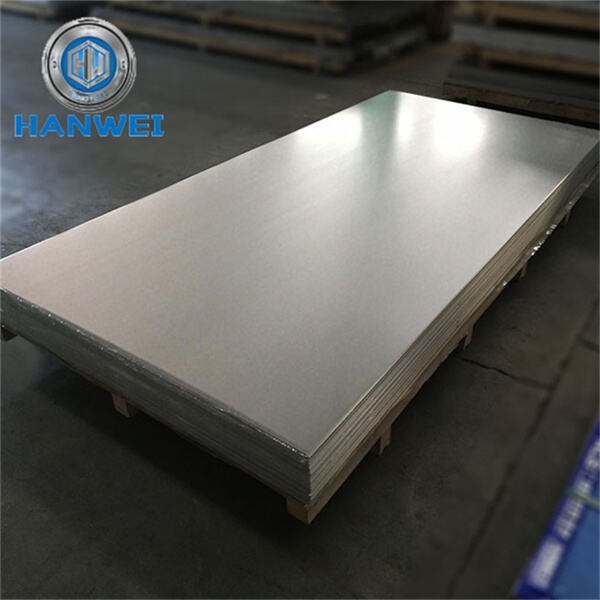

How Titanium Sheet is Made — Its really interesting! You start with a solid block of titanium. To begin with, this block is melted down to the point where it becomes a liquid. Next, the molten titanium is placed in a mold to form a giant flat sheet. Then, that sheet is rolled and pressed multiple times. That helps make it thinner but still strong.

Titanium can also withstand extremely high temperatures. The ability to withstand high temperatures makes it ideal for market sectors that deal with hot environments and materials such as engines or manufacturing processes that involve extreme heat. Besides, titanium is nonmagnetic. This unique property is used in medical tools & devices that need to be non-magnetic as it is for safety reasons.

Titanium Sheet is used in many different industries for different purposes. In aerospace, it is used to build the body and engines of airplanes, missiles, and rockets. In the medical field, it is also common in devices such as artificial joint replacements and dental implants, which must be strong as well as safe for human bodies. In sports, titanium is typically found in bicycle frames, as the strength and lightness of the metal make bicycles easier to ride and control.

Titanium sheet is absolutely transforming manufacturing in the modern world. It is enabling businesses to devise new products that are strong yet light. Due to its distinctive properties, titanium is at the forefront of enhancing product manufacturing in various areas, such as aerospace, automotive, and biomedical sectors.

And this awesome metal isn't only used in things like airplanes, medical devices, and sports equipment — it's also found in other things we are always using, like smartphones and laptops. Not to mention, it is resistant to water and chemicals, therefore providing the perfect protection for devices and making them have a longer term for users.

We adhere to the principle of "customer first" We are committed to providing flexible and personalized solutions that meet the specific needs of different customers. Through personalized and in-depth services we provide customers with not just products as well as overall solutions that meet their product design and application needs.

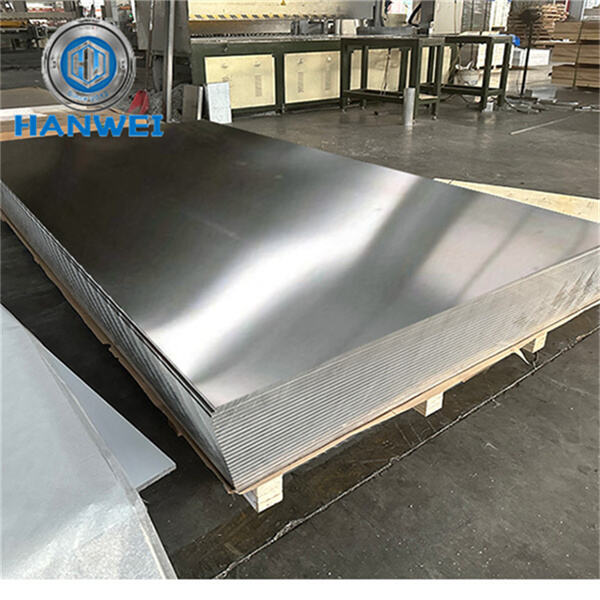

We stock a vast inventory of titanium, aluminum and other metals, available in a range of sizes and specifications to meet the needs of our customers. Our company has also developed its own logistics system that ensures products are delivered within the shortest time feasible. We can respond quickly to the needs of customers in a hurry with our flexible inventory management system and rapid delivery capabilities. This helps our customers cut down on time to production and boost efficiency.

Our professional after-sales staff will provide customers with quick technical assistance and assist in solving issues. Our after-sales personnel will give customers the best solutions regardless of whether they require custom cutting with consultation or feedback on quality problems. We also provide a frequent returning visit for customers to better understand their needs and to use their feedback.

With a broad range of market layout and a global service options, our goods are offered to a variety of regions and countries around the world, and cover important markets like Southeast Asia, Europe, and the Americas. The company has set up an international logistics network so that it can rapidly respond to the demands of its global customers. We also have a team of multilingual customer service representatives to offer professional technical support to our customers all over the globe.