Tungsten rod: There is a very special metal stick. It is composed of tungsten, which is incredibly strong and hard. In fact, tungsten is one of the heaviest metals in the world! This makes it really unique. Tungsten has several unique characteristics or properties, which make the metal highly useful across a wide range of applications or industries. This article explains : what it is, why it's so important, and how it's used in various ways.

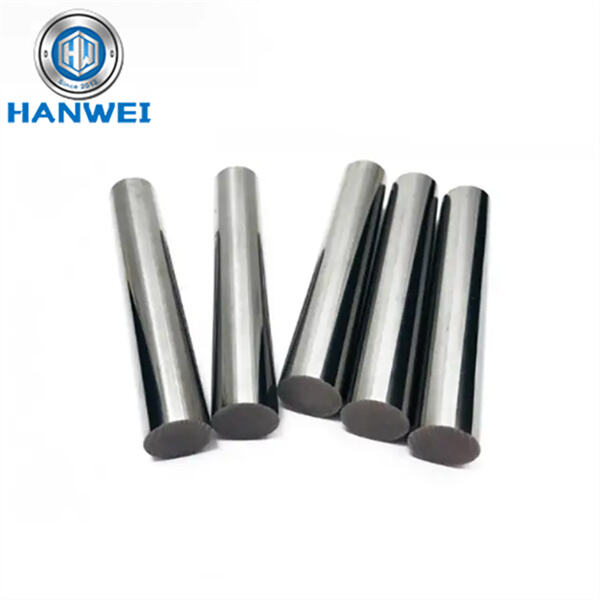

A tungsten rod is a specific kind of metal rod used for various things. It is made of tungsten, which is not only really hard, but also extremely dense, so it carries a lot of weight in a small volume. Some of the common uses where people use tungsten rod include welding, cutting, and drilling purposes. Actually, it has a great involvement to manufacture various types of tools and machines that we can see or use throughout the days. Thanks to its strength, tungsten rod is often used for many jobs across many industries, construction and manufacturing included.

Tungsten rod has many good reasons over any other materials. The biggest reasons is that it is super strong. This is why tungsten rod was used for making tools and machines, which have a very long life and don’t break easily. No one wants tools that easily break! Furthermore, tungsten rod does not rust easily or corroded. This is significant because it allows it to be used in much harsher conditions, such as wet or dirty locations, without getting ruined. These two properties make tungsten rod a good choice for workers.

Here are a few benefits of tungsten rod for various industry applications. One major benefit is that it is tough and can take a lot of abuse. When tungsten rod is used to make tools and machines, they can harden up and not break apart. Such durability matters when tools are used continuously, as in industrial applications. Furthermore, due to the fact that tungsten rod does not rust, you can use it in demanding environments without compromising the quality or usability of the tungsten rod. Having a high melting point, tungsten rod can also resist extremely high temperature jobs, such as welding, where heat is used for joining 2 pieces of metals.

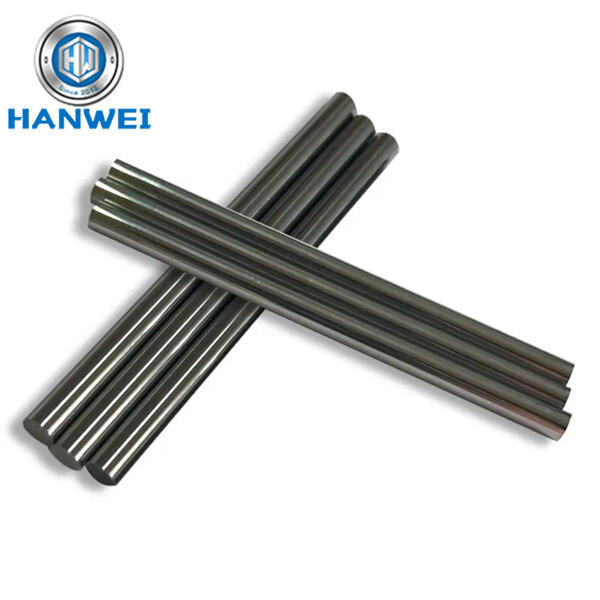

Tungsten rod MTI, terrific in assisting in extending the service life of tools and machines. Tungsten rod is extremely strong and can undergo a lot of stress, as we already know. This is why tungsten rod creates far more durable tools that are less likely to break or become damaged in use. In addition, tools manufactured with tungsten rod can last long term, even in tough situations, as it does not rust easily. Finally, tungsten rod has a high melting point so it can endure high temperatures without melting. This is also the reason why tools built using tungsten rod can always be relied on to perform well even when heat is called for.

Tungsten rod is one of the most entertaining things as it can be very strong as well as flexible. Tungsten rod is very versatile, which means they can be used for a variety of applications ranging from welding to cutting to drilling. This versatility allows for its application in many different jobs and industries, which makes it a very useful material. Tungsten rod is a strong and durable material, which means that tools and machines made of tungsten can withstand harsh working conditions. The strength lodged with the adaptability has galvanized tungsten rod an extraordinary decision for anybody who requires trustworthy hardware for their activity.

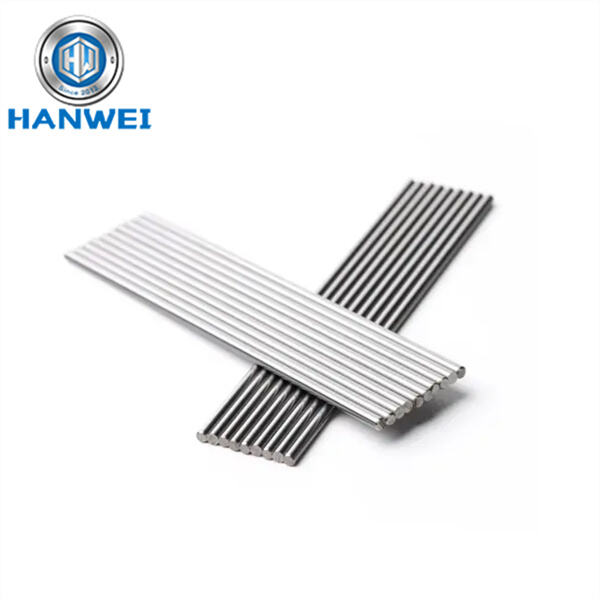

Our company stocks a huge inventory of aluminum, titanium and other metals, covering a variety of specifications and models to satisfy the requirements of different clients. The company also has its own logistics system, which makes sure that products will be delivered in the fastest time possible. Flexible inventory management and quick delivery capabilities enable us to quickly respond when customers have urgent needs and help customers cut production time and increase efficiency.

We have created a professional after-sales team that is able to provide customers with rapid response technical support and problem solving. Our after-sales personnel will give customers the best possible solutions, whether it's custom cutting and consultation, or providing feedback on issues with quality. Additionally, we offer a regular return visit service to understand customer needs and use feedback promptly in order to continually improve our customer service.

We're dedicated to providing customizable, flexible solutions that are able to meet the requirements of every customer. With personalized and comprehensive solutions We provide our customers with not just the materials they require as well as overall solutions that are in line with their specific product design and requirements.

With a diverse market layout and international service system, our products are available to various countries and regions around the world, covering major markets such as Southeast Asia, Europe, and the Americas. The company has built an entire international logistics system to ensure that it can swiftly respond to the needs of global customers. At the same time, we have a multilingual customer service staff to provide high-quality technical support and assistance to our customers all over the world.