Common Surface Finishes for Aluminum Sheets

Aluminum sheets are used in many applications such as marine, chemical, automotive, electronics, appliances and construction. Surface Finishes When it comes to aluminum sheets, surface finish is fundamental in determining its aesthetic appearance as well as function and lifespan. It is important and our intention to let you know the different types of aluminum sheet finish that exist to help you select the right one for your special project. From simple coatings to more sophisticated coatings, each choice has its own qualities to suit various applications and requirements. Let’s explore into the varieties of common surface finishes for aluminum sheets and see their applications in different industries

Guide to Stainless Steel Sheet Finishes

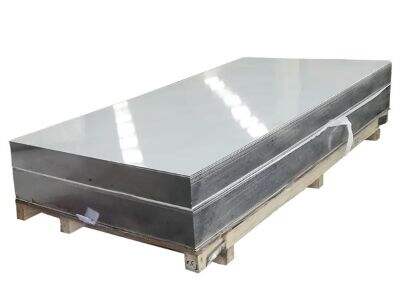

But when you decide to choose aluminum sheet finish options, there are many choices that you will be faced with, all of which have their own attributes and advantages. Easily the most popular of all surface finishes for aluminum sheet, mill finish comes out as a smooth, shiny and bright surface. This finish offers a nice bright, brushed appearance that will withstand daily use and mask the fingerprints, scuffs, scratches, etc. 2B (Bright, Cold Rolled) A bright, cold-rolled finish is the most commonly "Mill" finish for light gauge stainless. Anodized aluminum, another popular finish, is achieved by an electrochemical process that creates a protective layer of corrosion and weather-resistant finish on the sheet. For similar reasons, anodized aluminum is also used in construction, automotive, and even electronics sectors, to name a few

Investigations of Alternative Surface Preparation Modes for Aluminum Sheets

Apart from mill finish and anodized aluminum, the surfaces of aluminum sheets can also be treated to give special properties, such as reflectance, metal mark resistance, or scuff and two-side texturing. One of these treatments is powder coating that is applied as a free flowing, dry powder to the face of the sheet and baked to form a hard skin protective finish under the action of heat. Another surface treatment choice is brushed aluminum, after brushing the surface of the plate is obtained with a fine sand screen panel effect between the welding line and plating looks beautiful. It is great for interior design, home decor, furniture and consumer electronics

Aluminum Sheets : A Brief Introduction to Surface Finishes

Surface trim finishes are of a great importance of information on the properties, appearance, and property–related application of aluminum sheets. By choosing an appropriate finish, we can determine the level of corrosion, abrasion, UV resistance and overall performance and aesthetic value that the sheet can offer and it is therefore important to identify the best finish for a specific project. For instance, an outdoor product where durability and weathering are critical may require a powder-coated finish whereas a brushed finish may be more appropriate for a decorative or upscale product where looks matter most. By knowing how critical surface finishes are for aluminum sheets, both manufacturers and designers can make the right choices and achieve great results for their projects

Choosing Between the Electric and Pneumatic Staplers For Your Project

When choosing a finish for aluminum sheet, it’s critical to consider your application end-use requirements, desired surface appearance, and desired function of the surface. To understand these finish types and to make sure you’re getting a finish that will last, consult with industry professionals and vendors like Shanghai Hanwei and select the right finish for your specific application. If you are after a clean, modern aesthetic for an architectural cladding product, most likely a UV and weather resistant finish for outdoor furniture, a premium look for a consumer electronic, there is a surface finish for you. By selecting the most appropriate for your application, you can optimize the performance of your aluminum sheets and successfully achieve your design goals

The surface finish world of aluminum sheet stock is a mysterious place -- there are no fewer than five terms that describe the type of finish you are ordering. Deep in the bowels of the aluminum supply chain lies a world that few of us are fully aware of: The shiny, shiny world of aluminum surface finishes. With plain mill finish, all the way to advanced treatments such as anodizing, powder coating and brushing, each of these finishes has its own properties and advantages. By taking into consideration the significance of surface finishes, as well as the criteria of the project, manufacturers and designers can obtain high-quality results for their projects. Thanks to the expertise from professionals and manufacturers which includes Shanghai Hanwei, you will be on your way to flow on seamlessly choosing from a wide range of surface finish options of aluminum sheets, without any worries wondering which finish would be ideal to realize your vision