Titanium is a lustrous and most powerful and by the strongest rev of them all. All of these factors make titanium a very useful material in medicine. Bone surgeons and doctors, use titanium to form rods used to treat people with broken bones. These rods can hold the bone steady as it heals. They’re flexible, so you can bend them a bit. These rods can bend to adapt to the shape of the bone—an instance where in-line fixators are considered quite valuable during cases of bone integrity.

However, if someone has a broken bone it is painful. A titanium rod can be used by the doctor to help the bone heal appropriately. This involves the placing of the rod into the broken bone through a small incision in the skin made by the doctor. This wound is tiny so that healing can be faster. The physician guides that rod, carefully, into the bone using specialized equipment. After a rod has been placed, it offers support to the bone as it heals. The bone eventually grows around the rod, which further strengthens the bone. This process allows the bone to heal more quickly compared to when a rod is not inserted.

There is always a tight race for athletes, people who play sports, to ameliorate their performance and perform significantly better in their game. Titanium rods are of great help for athletes. Titanium is an ideal material for sports gear because it is big, light and tormented. For instance, titanium rod-based tennis rackets are significantly lighter and more durable than ordinary rackets. This is immensely helpful for the players as it lowers their fatigue in the matches and lets them strike the ball with more strength and velocity. In addition to tennis rackets, titanium rods are used in golf clubs, bicycles and many other types of sports equipment. Titanium's versatility enables manufacturers to craft equipment in tremendous fluctuations of shapes and sizes, which is incredibly helpful for most athletes.

Scientists and engineers constantly discover new uses for titanium, making it even more precious than it already is in medicine and other ways. This new procedure is referred to as “three-dimensional (3D) printing.” Doctors and scientists can then make tailor-made titanium rods for each patient. The process involves melting small pieces of titanium and then layering them up into whatever shape is needed. This is immensely helpful as every body is different, so a custom rod can slot right into the exact bone in need of extra support. By tailoring decisions to patients, this would enhance healing.

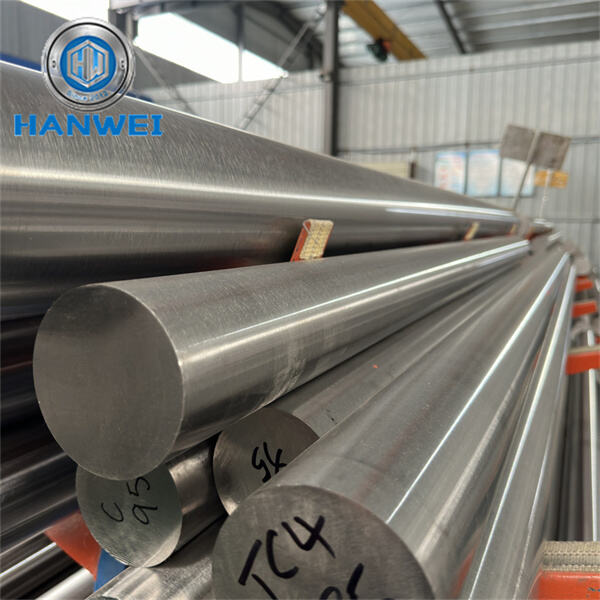

Titanium rods are widely used in both medicine and industry. And not only are they light, they are some of the strongest materials in existence; they are used in things like airplanes and spacecraft. Because titanium doesn’t rust easily, it can be used in underwater settings, such as oil rigs and submarines, where it is important that things last. In addition, titanium rods can be used as structural supports in buildings and bridges, helping to keep them safe and steady. Titanium's sturdy nature means that it can withstand high loads, but it is light enough that it can minimise the potential for added weight to projects.

With a variety of market layout and a global service options, our goods are offered to a variety of regions and countries around the world, encompassing major markets such as Southeast Asia, Europe, and the Americas. The company has established an entire international logistics system to ensure it is able to quickly meet the demand demands of its global customers. Additionally we have a multi-lingual customer service staff to provide skilled technical support and services for customers from all over the world.

We have set up a highly skilled after-sales department, which is able to give customers fast response technical support and assistance in solving issues. Our after-sales personnel will give customers the best possible solutions whether it's cutting custom, using consultation or feedback on quality issues. We also offer a regular return visit to customers to better understand their requirements and use their feedback.

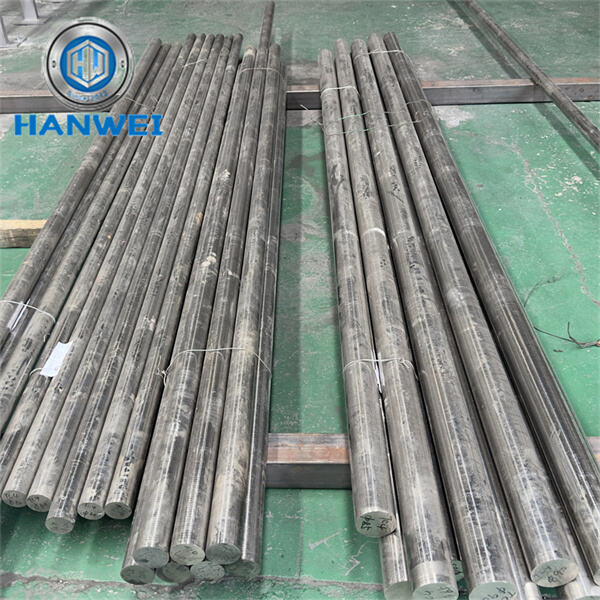

The company's inventory is extensive. assortment of titanium, aluminum and other metal materials, with a wide range of models and specifications to meet the requirements of our customers. Additionally, the company has built its own logistics system to ensure that the items are delivered to customers in the fastest possible time. Flexible inventory management and fast delivery capabilities enable us to be able to respond quickly when customers have urgent needs to help them save production time and increase efficiency.

We're dedicated to providing flexible, personalized solutions that meet the demands of each client. Through personalized and in-depth services we provide customers with not just materials but also complete solutions that are in line with their application and design needs.