औद्योगिक निर्माण में, एक एल्यूमीनियम सामग्री है जो मशीनिंग की नाजुक आवश्यकताओं को पूरा कर सकती है और साथ ही साथ दैनिक वातावरण के संक्षारण परीक्षणों का सामना कर सकती है। यह लागत और प्रदर्शन के बीच संतुलन भी बना सकती है। यही है 6061 एल्यूमीनियम। विभिन्न उद्योगों में 6061 को "पसंदीदा" बनाने की कुंजी इसकी "सार्वभौमिक और संतुलित अनुकूलनीयता" विशेषता है। यह अधिकांश औद्योगिक परिदृश्यों की मुख्य आवश्यकताओं को पूरा कर सकती है बिना किसी एकल प्रदर्शन के लिए अत्यधिक समझौता किए।

संरचना की दृष्टि से, 6061 एल्यूमीनियम मिश्र धातुओं की Al-Mg-Si श्रृंखला में आता है। मैग्नीशियम (लगभग 0.8% - 1.2%) और सिलिकॉन (लगभग 0.4% - 0.8%) तत्वों को जोड़कर तथा एक विलयन उपचार + कृत्रिम आयु प्रक्रिया के माध्यम से, यह "ताकत, लचीलापन और संक्षारण प्रतिरोध" के संतुलन की एक सुनहरी बराबरी प्राप्त करता है: इसकी तन्य शक्ति 276MPa से अधिक तक पहुँच सकती है, जो यांत्रिक संरचनात्मक भागों की तनाव आवश्यकताओं को पूरा करने के लिए पर्याप्त है। इसके साथ ही, इसमें अच्छी लचीलापन होता है और इसे मोड़ना, स्टैम्प करना और वेल्डिंग जैसी प्रक्रियाओं से आसानी से गुजारा जा सकता है। भले ही जटिल आकार के भाग हों, उन्हें भी सटीक रूप से आकारित किया जा सकता है। अधिक महत्वपूर्ण बात यह है कि इसमें कुछ संक्षारण प्रतिरोध होता है। नमी वाले वातावरण या हल्के रासायनिक संपर्क परिदृश्यों में, इसका उपयोग लंबे समय तक किया जा सकता है और इसके लिए किसी अतिरिक्त जटिल उपचार की आवश्यकता नहीं होती है, जिससे बाद की रखरखाव लागत में काफी कमी आती है।

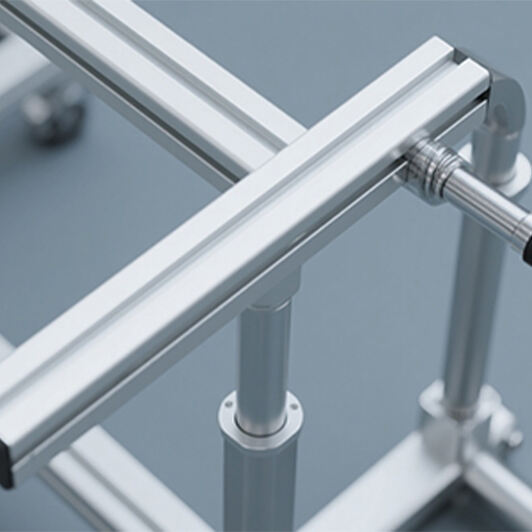

इस संतुलित विशेषता के कारण 6061 औद्योगिक क्षेत्र में लगभग "हर जगह उपलब्ध" है: ऑटोमोटिव निर्माण में, इसका उपयोग अक्सर चेसिस ब्रैकेट और दरवाजे के फ्रेम बनाने के लिए किया जाता है - यह न केवल वाहन के वजन और ड्राइविंग के दौरान होने वाले कंपन का सामना कर सकता है बल्कि हल्केपन के माध्यम से ऊर्जा खपत भी कम कर सकता है। मेडिकल डिवाइस के क्षेत्र में, 6061 की सरल मशीनीयता इसे सटीक सर्जिकल उपकरणों के कैसिंग और पुनर्वास उपकरणों के ब्रैकेट बनाने में सक्षम बनाती है, और इसकी चिकनी सतह को डिसइंफेक्ट और साफ करना भी आसान होता है। यहां तक कि सामान्य रूप से देखे जाने वाले औद्योगिक शेल्फ और स्वचालित उपकरणों के संचरण भाग भी 6061 को प्राथमिकता देते हैं - क्योंकि यह उच्च लागत के बिना "भार वहन करने पर विकृति न होना", "बिना जंग लगे लंबे समय तक उपयोग करना" और "बड़े पैमाने पर उत्पादन के लिए सरल प्रसंस्करण" जैसी तीन मुख्य आवश्यकताओं को एक साथ पूरा कर सकता है।

एविएशन-ग्रेड एल्युमीनियम सामग्री के उच्च शक्ति पर केंद्रित होने और मरीन-ग्रेड एल्युमीनियम सामग्री के जम्मू प्रतिरोध पर जोर देने के विपरीत, 6061 की विशेषता इसकी "सर्वांगीण क्षमता" में है। यह किसी एक विशेषता में "चैंपियन" तो नहीं हो सकता, लेकिन एक "सर्वांगीण खिलाड़ी" है, जो 80% औद्योगिक परिदृश्यों में अनुकूलन कर सकता है। ठीक इसी "पर्याप्त, उपयोगकर्ता-अनुकूल और लागत प्रभावी" संतुलित अनुकूलनीयता के कारण 6061 कई औद्योगिक उद्यमों के लिए एल्युमीनियम सामग्री खरीदते समय "प्राथमिकता वाला विकल्प" बन गया है और यह सामान्य औद्योगिक एल्युमीनियम सामग्री बाजार का आधा हिस्सा भी सुदृढ़ रूप से समेटे हुए है।

हॉट न्यूज

हॉट न्यूज2026-01-29

2026-01-27

2026-01-22

2026-01-20

2026-01-15

2026-01-13