وەکو سەختترین ئالیاژ لە زنجیرەی 6xxx، پلەی ئالۆمینۆمی 6082 بەهۆی تێکەڵەی سەرەکی ماگنیسیۆم-سیلیکۆن و رێزای کردنی دانەی منگنێز دەست لە هەمووان بەدەست دەهێنێت. لەگەڵ بەدەستهێنانی مامکردنەوەی نموونەی ASTM B209 و EN 573-3، بەهێزی کشاندنی T6-temper بەردەوام لە نێوان 380-420MPa دابین دەکات—کە بەهێزتر لە 6061 و 30% دامەزراندنی کەمتر لە 7075 هەیە—کە دیاری دەکات بەهۆیەکی باوەڕپێکراو بۆ دۆخە کاریگەرییەکانی سازوکاری لەسەرانسەری جیهان.

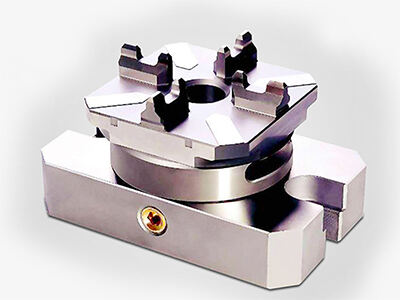

بەهێزی قوربان: حاڵەتی T6/T651 بەهێزی گواستنەوە ≥310MPa و بەهێزی بەربەستبوونی خستنەوەی 120MPa دابین دەکات، کە یارمەتیدەری بارکردنی بەردەوام و پایداری بۆ ئامرازە سازوکارییەکان دەبێت.

بەربەستنی قوربان بە دووواندن: فۆرمۆلەی گەشەپێدراوی منگنێز دەتوانێت زیاتر لە 2000سا عەکس بەسەر ماوەکان ببات، و لە ناوچە دەریایییەکان، کرانەدا، و جۆرە ژینگە شۆرشەوارەکانی سەنەدی بە باشی کاردەکات.

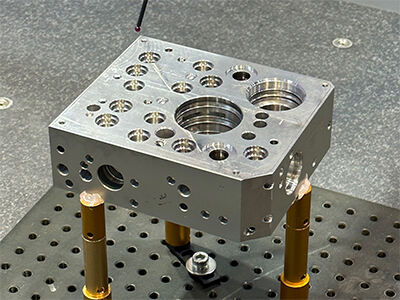

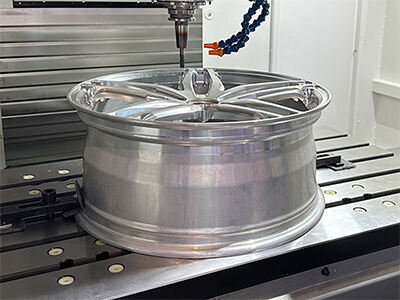

درۆستکردنی باوەڕپێکراو: 75%+ بەهێزی دووبارە دەگرێتەوە دوای کردنی لەوەی TIG/MIG؛ دەتوانێت دەقی ±0.2mm بۆ دروستکردنی ئامرازە سازوکارییە ئاڵۆزەکان بەدەست بێنێت، و بە باشی دەتوانرێت ماشین بکرێت.

هاوکاریی بهرە و نرخ: توانای ساختاری 7075 بە نرخێکی نزمتر دابین دەکات، بەبێ کاستن لە نێوان قورسی و بودجە.

ئەندازیاری دەریایی: دەکەم، دیوارەکان و بۆلاردەکانی بەندکردن—کەم دەکاتەوە 15% لە کێشی دەمەزەکە و لە کاتێکدا لە بەرەنگاری پێکهاتنەوەی ئاوی دەریا دەمەوێت.

ئامێری پیشەسازیی قورس: بازووی کاکاوژەکان و بازووی کرەینە تەلیسکۆپییەکان—بەهێزی بەکارهێنانی پۆشەکان دەگەیەنێت بە 20% بەهۆی بەرگری بەهێز لە شکاندن.

گواستنەوەی قورس: کەفەلی شاسی کرۆک و ئامێرەکانی گواستنەوەی ڕێلی—هەمواری دەکاتەوە نێوان شێوازی ئاسان و توانای گرتنی باری قورس.

بنەما: پانەلەکانی پلی بەرەوپێشچوو و یارمەتی دیوارەکانی فولادی—گونجاندن بۆ مامەڵەکانی دەرەوە و دانانی ئاسان.

ئێمە ١٠,٠٠٠ تۆن پلەی ئالیومینیۆمی ٦٠٨٢ (دۆخی T6/T651) دابین دەکەین، کە ناوبەری ١-٦٠٠ مم بەرزی و تا ٣٠٠٠ مم بەردەستە. خزمەتگوزاری بڕینی تایبەت، پێشداچوونی لە پێدان و هاوتاکردنی بەشە سترۆکتۆرال بەردەستە. ستاندەردی ستوونی ٢-٧ ڕۆژ دەردەکەوێت، گزارەی ئازموونی کشان و پسیلکردنی گروپی دابین دەکرێت. بۆ پڕۆژە گەورەکان، تیمی تەکنیکی چارەسەری پرۆسەکردنی تایبەت دابین دەکات.

Nûçeyên Girîng

Nûçeyên Girîng2026-01-29

2026-01-27

2026-01-22

2026-01-20

2026-01-15

2026-01-13