ອາລູມິນຽມ 5083, ເຊິ່ງເປັນໂລຫະອາລູມິນຽມ-ແມກນີຊຽມ (Al-Mg) ທີ່ມີແມກນີຊຽມປະມານ 4.0%-4.9%, ໄດ້ຖືກອອກແບບມາເພື່ອໃຫ້ດີເດັ່ນໃນສະພາບແວດລ້ອມທີ່ຮ້າຍແຮງ - ໂດຍສະເພາະວິສະວະກຳທະເລ ແລະ ສະຖານທີ່ນອກສະຖານທີ່ທີ່ມີນ້ຳໜັກເບົາ - ເຊິ່ງຄວາມຕ້ານທານກັບການກັດກ່ອນ ແລະ ຄວາມເຂັ້ມແຂງແມ່ນບໍ່ສາມາດປະນີປະນອມໄດ້. ຕ່າງຈາກໂລຫະທົ່ວໄປທີ່ພົບວ່າບໍ່ສາມາດຢູ່ລອດໃນນ້ຳທະເລ ຫຼື ລົມແຮງ, ມັນສາມາດຮັກສາຄວາມສົມດຸນທີ່ສຳຄັນລະຫວ່າງຄວາມຍືນຍົງ, ຄວາມແຂງແຮງ ແລະ ນ້ຳໜັກເບົາໄດ້.

ຄວາມເຂັ້ມແຂງຂອງມັນມາຈາກປະກອບສ່ວນຂອງມັນ: ແມກນີຊຽມໃນລະດັບສູງສ້າງເປັນຊັ້ນອົກຊີດທີ່ຫນາແໜ້ນ ເຊິ່ງຊ່ວຍກັ້ນກິນໄອອິໂລດໃນນ້ຳທະເລ, ເຮັດໃຫ້ມີຄວາມຕ້ານທານການກັດກ່ອນໃນສະພາບທະເລດີຂຶ້ນ 40% ກ່ວາອາລູມິນຽມ 5052. ມັນຍັງມີຄວາມເຂັ້ມແຂງຕໍ່ການດຶງ (tensile strength) ຢູ່ໃນຂອບເຂດ 275-350 MPa (1.5 ເທົ່າຂອງ 5052) ເພື່ອຕ້ານທານກັບການກະທົບ, ແຕ່ຍັງມີນ້ຳໜັກເບົາກ່ວາທາດເຫຼັກ 35% - ຊ່ວຍໃຫ້ການຕິດຕັ້ງ ແລະ ການຮັບນ້ຳໜັກຂອງໂຄງສ້າງງ່າຍຂຶ້ນ.

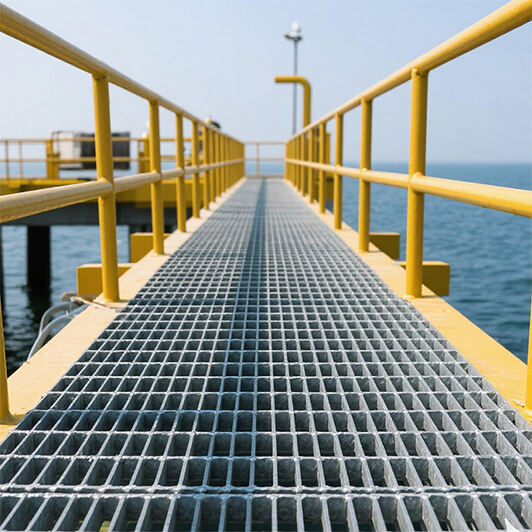

ໃນວິສະວະກໍາເຮືອ, 5083 ແມ່ນສິ່ງທີ່ຈໍາເປັນ. ເຮືອຂະ ຫນາດ ນ້ອຍຫາກາງໃຊ້ມັນ ສໍາ ລັບຊັ້ນແລະອຸປະກອນທໍ່ໃຕ້ນ້ ໍາ: ມັນທົນທານຕໍ່ການຈົມນ້ ໍາ ທະເລດົນນານໂດຍບໍ່ມີຮູຫລືຮົ່ວໄຫລ, ຫຼຸດຄ່າໃຊ້ຈ່າຍໃນການ ບໍາ ລຸງຮັກສາ 30% (ບໍ່ມີການ ກໍາ ຈັດ rust ເລື້ອຍໆ). ບັນດາເວທີທີ່ຢູ່ ນອກທະເລ ແມ່ນເພິ່ງພາອາໄສມັນ ສໍາລັບຮົ້ວທາງຍ່າງ, ຍ້ອນວ່າມັນຕ້ານທານກັບຫມອກເກືອ 24 ຊົ່ວໂມງຕໍ່ 7 ມື້ ເພື່ອຮັກສາຄວາມປອດໄພຂອງຄົນງານ.

ສໍາລັບໂຄງສ້າງກາງແຈ້ງທີ່ໃຊ້ໄດ້ຫນັກ ມັນຍັງສ່ອງແສງໄດ້ ກອບປ້າຍໂຄສະນາຂະຫນາດໃຫຍ່ໃຊ້ມັນເພື່ອຕ້ານລົມລະດັບ 12+, ຫຼີກລ້ຽງການພັງລົງຂອງພາຍຸ. ຂົວຂົວແລະເວທີການຮັກສາໄດ້ຜົນປະໂຫຍດຈາກຄວາມຕ້ານທານຕໍ່ການ corrosion ບໍ່ມີການປັ້ນປີແລະນ້ ໍາ ຫນັກ ເບົາຫຼຸດຜ່ອນພາລະຫຼັກຂອງຂົວ, ຍືດອາຍຸການໃຊ້.

5083 ບໍ່ແມ່ນຈຸດປະສົງທຸກຢ່າງ (ມັນຕໍ່ສູ້ກັບຄວາມຮ້ອນສູງ), ແຕ່ໃນສະພາບການທາງທະເລແລະກາງແຈ້ງທີ່ ຫນັກ, ຄວາມສາມາດໃນການຕອບສະ ຫນອງ ຄວາມຕ້ອງການຄວາມ ຫນ້າ ເຊື່ອຖືຢ່າງແນ່ນອນເຮັດໃຫ້ມັນບໍ່ມີການທົດແທນ. ມັນບໍ່ແມ່ນວັດສະດຸດຽວນີ້ ມັນເປັນວິທີແກ້ໄຂທີ່ ຫນ້າ ເຊື່ອຖື.

ຂ່າວຮ້ອນ

ຂ່າວຮ້ອນ2026-01-29

2026-01-27

2026-01-22

2026-01-20

2026-01-15

2026-01-13