In industrial production, many critical components operate non-stop—for example, aircraft parts undergo takeoffs and landings with daily flights, racing car components endure constant vibrations on the track, and machine shafts in factories run at high speeds 24 hours a day. These parts withstand hundreds or even thousands of cycles of high-frequency vibration and instantaneous impact every day. For them, "fatigue resistance" (the ability to resist cracking and sudden fracture under repeated stress) is more important than mere "hardness." And 2024 aluminum alloy is widely recognized as a reliable "workhorse" for such high-frequency stress scenarios.

Some may wonder, isn’t "fatigue resistance" just withstanding pressure? Actually, it’s different—many materials can withstand a single heavy impact, but repeated small-force "wear and tear" is more likely to "wear out" the material. For instance, parts made of ordinary aluminum may develop invisible micro-cracks on their surfaces after just a few hundred aircraft takeoffs and landings or a few thousand kilometers of racing. Over time, this poses a fracture risk. However, identical parts made of 2024 aluminum alloy can withstand tens of thousands of cycles without issues. This gap in fatigue resistance stems from 2024 aluminum alloy’s specialized "composition" and "processing method": based on pure aluminum, it intentionally incorporates 3.8%-4.9% copper as the "primary strengthener," which acts like tiny "support pillars" built inside the material. A small amount of magnesium and manganese is also added to optimize the structure, making the material more durable. After that, it undergoes T3 or T4 heat treatment: T3 involves heating to integrate alloying elements uniformly into the aluminum matrix, rapid cooling to lock in the structure, light cold working, and final natural aging for stabilization; T4 involves solution treatment followed directly by natural aging. Both processes densify the internal structure, ultimately giving it a rotating bending fatigue strength of 105MPa. Simply put, even if a force of 10.5 kilograms is repeatedly applied to each square centimeter of the material, it remains stable over the long term—this is more than twice the fatigue resistance of ordinary pure aluminum (which has a fatigue strength of only about 50MPa).

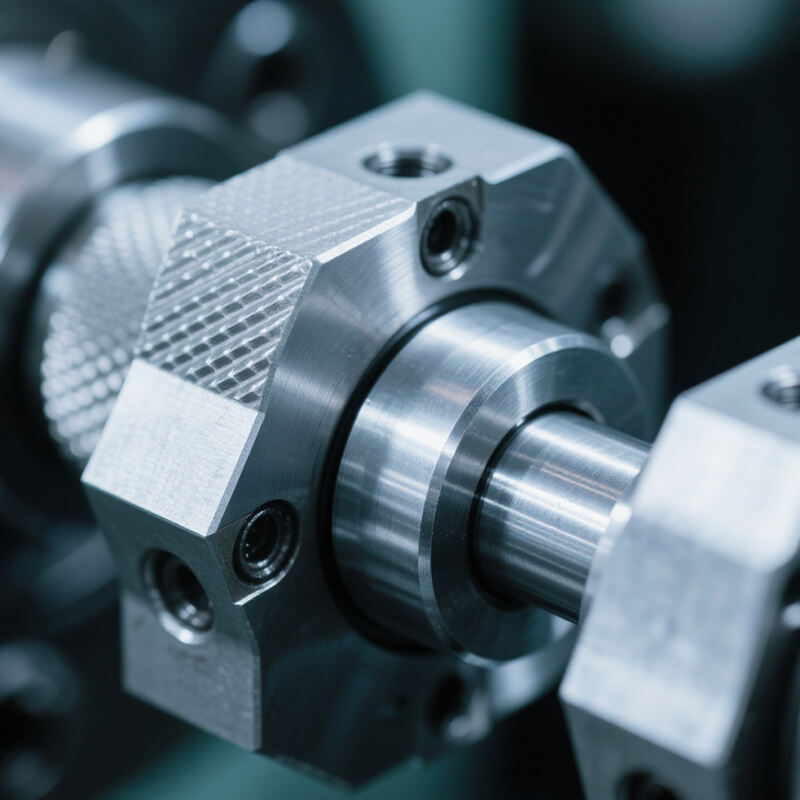

Thanks to this property, 2024 aluminum alloy has become an "essential material" in multiple industries. In the aviation sector, critical parts like aircraft wing connection brackets and fuselage frames must withstand continuous vibration from airflow during flight, as well as the sudden "thud" impact during takeoffs and landings. The consequences of fatigue cracks here would be catastrophic. Parts made of 2024 aluminum alloy not only easily withstand tens of thousands of takeoff and landing cycles but also have a service life that can even exceed the aircraft’s design life, directly safeguarding flight safety. In the racing industry, engineers want parts that are "strong enough to resist vibrations" but fear excessive weight will hinder speed. 2024 aluminum alloy solves this dilemma perfectly—it is only 1/3 the weight of steel. Suspension arms made from it can withstand hundreds of bumpy impacts per kilometer on the track while reducing the vehicle’s weight, enabling faster acceleration and more agile cornering. Even in regular factory equipment, such as high-speed punch press slider connecting shafts and precision centrifuge rotor brackets, these parts rotate thousands of times per minute, equivalent to being repeatedly "pulled" every second. Previously, with ordinary aluminum, shafts had to be replaced almost monthly, leading to high costs and production delays. After switching to 2024 aluminum alloy, the maintenance cycle is extended to 3-4 months, saving significant costs from production downtime alone.

In summary, the advantage of 2024 aluminum alloy is not "brute-force resistance"—it may not match some steels in hardness, but in terms of "wear-resistant" fatigue resistance, combined with the inherent advantage of lightweight, its value is hard to replace in scenarios requiring resistance to repeated vibration and impact. If you’re looking for an aluminum material for your products that can withstand high-frequency stress over the long term while reducing weight, 2024 aluminum alloy may be the choice that helps you improve product reliability and lower subsequent maintenance costs.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-22

2026-01-20

2026-01-15

2026-01-13