In high-stress sectors like aerospace and automotive manufacturing, fatigue resistance—resistance to repeated loading failure—is pivotal for component longevity. As a high-strength 2xxx-series aluminum-copper alloy, 2017 aluminum plate stands out in this key performance metric, thanks to its tailored alloy design and processing.

2017’s strength against cyclic stress stems from three key factors:

Copper-rich precipitates: Nano-sized Al₂Cu precipitates block dislocation movement, slowing crack initiation under repeated loads.

Fine grain structure: Controlled thermomechanical processing creates equiaxed grains that distribute stress evenly, reducing localized damage.

Surface optimization: Smooth machining (Ra ≤ 1.6 μm) and anodizing (8–15 μm oxide layer) minimize stress concentration points.

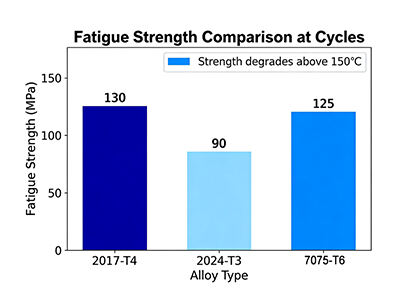

After T4 heat treatment, its fatigue strength reaches 130 MPa at 10⁷ cycles—outperforming 2024-T3 (90 MPa) in cyclic scenarios and maintaining stability at elevated temperatures (up to 150°C) better than 7075-T6.

Aerospace: Wing ribs and fuselage frames rely on its durability to endure millions of flight cycles, cutting maintenance costs by 30% vs. 6061-T6.

Automotive: Suspension arms and CV joint housings withstand road vibrations, lasting 30% longer than 5052-H32 alternatives.

Heavy Machinery: Hydraulic cylinders in mining equipment offer 2–3x longer service life compared to cast iron.

Prioritize T4 heat treatment for optimal fatigue resistance (T6 boosts static strength but reduces cyclic durability).

Adopt Type II anodizing or powder coating to prevent corrosion-induced fatigue cracks.

Avoid rough machining surfaces to eliminate stress concentration risks.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-22

2026-01-20

2026-01-15

2026-01-13