As a core member of the 2xxx series aluminum-copper alloys, 2014 aluminum plate dominates sectors requiring extreme strength and durability. But what makes it a go-to for aerospace, automotive, and heavy machinery? Its alloy composition, mechanical performance, and tailored usability hold the key.

Core Traits & Alloy Makeup

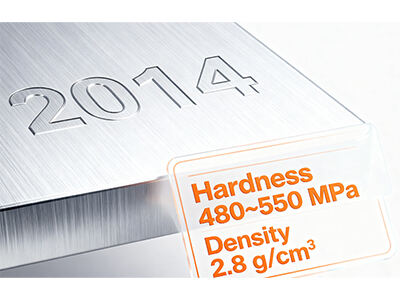

2014 aluminum plate relies on 3.9–5.0% copper (the primary strengthening element), plus manganese (0.4–1.0%) and magnesium (0.2–0.8%) for synergy. After T6 heat treatment, its tensile strength hits 480–550 MPa—far outperforming alloys like 6061-T6 (≈276 MPa). It also balances lightness (density: 2.8 g/cm³) with toughness, resisting fatigue under repeated loads.

Processability & Corrosion Protection

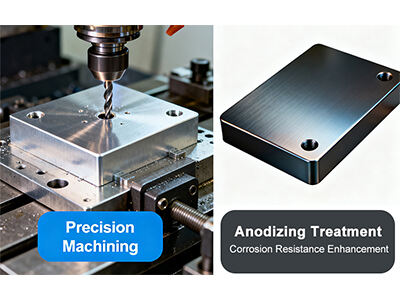

It excels at precision machining (milling, drilling) but requires careful welding—TIG welding with ER2319 filler is recommended to avoid hot cracking. For corrosion resistance in harsh environments (humid/chemical), surface treatments like anodizing or powder coating are essential.

Key Industry Applications

Aerospace: Used for aircraft fuselage frames and wing ribs—its high strength-to-weight ratio reduces aircraft weight while ensuring safety.

Automotive: Deployed in engine cylinder blocks and brake calipers to boost power and durability.

Heavy Machinery: Chosen for hydraulic cylinders and gearbox housings, as it withstands high pressure and mechanical stress.

Conclusion

2014 aluminum plate’s mix of high strength, toughness, and workability makes it indispensable for high-stress industries. While it needs targeted solutions for corrosion and welding, its performance ensures it remains a staple in aerospace, automotive, and beyond.

Hot News

Hot News2026-01-29

2026-01-27

2026-01-22

2026-01-20

2026-01-15

2026-01-13